Part 3: HEPA & Carbon Filters for Labs: Types, Uses, and Maintenance Tips

🧭 The Role and Types of Filters

The cleaning performance of local exhaust type and air purifying type of mobile fume extractors depends on the filters inside. Jeio Tech’s mobile fume extractors uses three main filters below:

| Pre Filter |  |

• Included as standard • First stage, captures larger particles and extends the life of other filters |

| HEPA Filter |  |

• Removes 99.97% of toxic dust and fine particles at the most difficult-to-capture size of 0.3㎛ |

| Carbon Filter |  |

• Removes a wide range of gases and odors • The surface is treated with catalyst, which enhances not only physical adsorption but also chemical adsorption(chemisorption), making it highly efficient. |

🔍 About the Jeio Tech HEPA Filter

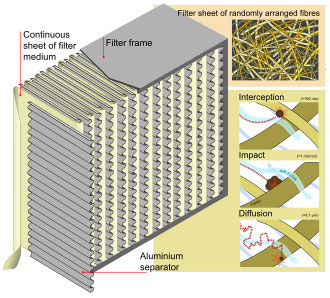

Structure of HEPA Filter |

HEPA (High Efficiency Particulate Air) filters are designed to capture small particles. To qualify as HEPA, a filter must remove at least 99.97% of particles sized at 0.3 μm. HEPA filters are made of layers of fine fibers that capture dust, allergens, fine dust, mold spores, and even viruses. They use physical trapping principles: as particles hit the fibers, they get caught, leaving the air cleaner. |

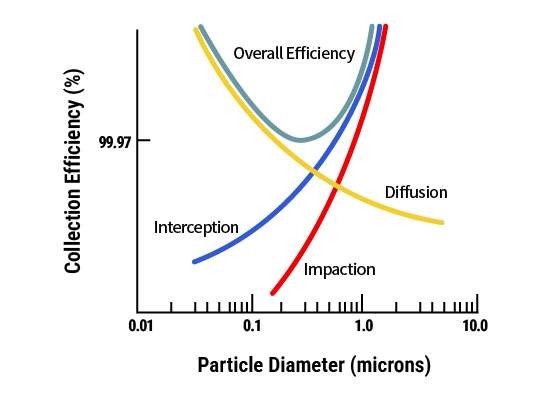

HEPA filter works through three mechanisms depending on particle size: large particles (>1 μm) are trapped by impaction, mid-sized particles (0.3–1 μm) by interception, and tiny particles (< 0.1 μm) by diffusion. When combined, these mechanisms form a U-shaped efficiency curve (the green line in the graph), with 0.3 μm at the lowest point. So remember:1) 0.3 μm represents the hardest-to-filter size (MPPS) for HEPA filter.

HEPA filter works through three mechanisms depending on particle size: large particles (>1 μm) are trapped by impaction, mid-sized particles (0.3–1 μm) by interception, and tiny particles (< 0.1 μm) by diffusion. When combined, these mechanisms form a U-shaped efficiency curve (the green line in the graph), with 0.3 μm at the lowest point. So remember:1) 0.3 μm represents the hardest-to-filter size (MPPS) for HEPA filter.2) Even tiny nanoparticles can be effectively filtered.

3) In practice, factors like airflow, leak prevention, and pre-filters are key to maintaining performance.

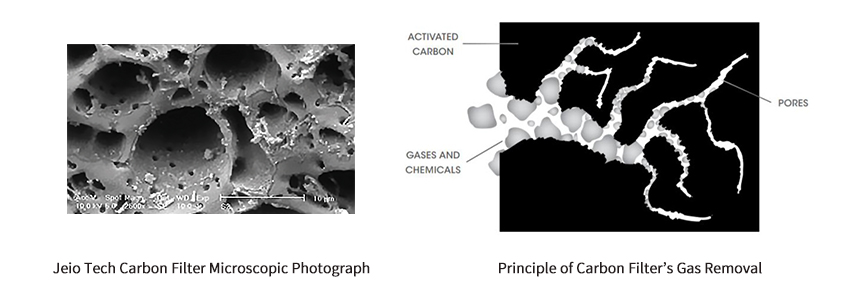

🔍 What Makes Jeio Tech’s Carbon Filter Special?

Activated carbon filters are highly effective for removing odors, harmful gases, and chemical vapors. The principle is adsorption—pollutants stick to the surface of the filter. Jeio Tech’s activated carbon filters go further. The surface is specially treated to enable chemical adsorption (chemisorption) in addition to physical adsorption. This makes them much more efficient than standard carbon filters. Click below to see the adsorption efficiency of standard carbon filters by chemical type. In this chart, chemicals that show only an F (Fair) grade with standard carbon filters reach G (Good) grade or higher when filtered through Jeio Tech’s carbon filters. 👉 Click here to check the adsorption efficiency of standard carbon filters by chemical type.

Jeio Tech’s activated carbon filters go further. The surface is specially treated to enable chemical adsorption (chemisorption) in addition to physical adsorption. This makes them much more efficient than standard carbon filters. Click below to see the adsorption efficiency of standard carbon filters by chemical type. In this chart, chemicals that show only an F (Fair) grade with standard carbon filters reach G (Good) grade or higher when filtered through Jeio Tech’s carbon filters. 👉 Click here to check the adsorption efficiency of standard carbon filters by chemical type.

✅ Types of Jeio Tech Carbon Filters

Refer to the table below to select the right filter based on the chemicals you use.

| Jeio Tech’s Activated Carbon Filter | Complex Carbon | Filters a broad range of chemicals, including acids, ammonia, aldehydes, etc. |

|---|---|---|

| Acid | Filters acidic gases like hydrogen chloride(HCI), hydrogen fluoride(HF), and hydrogen sulfide(H₂S), and acetic acid(CH₃COOH). | |

| Formaldehyde | Filters aldehydes such as formaldehyde and acetaldehyde. | |

| Ammonia / Amines | Filters basic gases like ammonia(NH₃) and trimethylamine(CH₃)₃N. |

🔄 When Should Filters Be Replaced?

Filter replacement timing can vary depending on the user’s environment, so there is no single fixed schedule. However, we recommend the following inspection and replacement guidelines:

(In dusty or heavy-chemical environments, check and replace more often than the recommended schedule.)✔️ Pre Filter• Check and clean the filter every week and replace approximately every 3months.✔️ HEPA Filter• Inspect once a year for clogging and replace if necessary.• How to Self-Check for blockage (pressure drop)• You can use a differential pressure gauge to check for blockages. • A clean filter shows low pressure drop. Over time, as dust/particle build up on the HEPA filter, airflow is restricted and the pressure drop increases. For this reason, it is recommended to check the differential pressure every year and replace the filter if the reading has risen significantly compared to the initial installation.

Exanple of HEPA filter check

(using a ditterential pressure gauge)• For example, in Jeio Tech’s clean benches, a rise of more than 25 mmAq from the initial value indicates that the filter is saturated and should be replaced. (The exact value may differ by product, so please refer to the user manual for your specific model.) ✔️ Carbon Filter• Check carbon filters for saturation every 3 months and replace it every 6 to 12 monthsdepending on use.• How to Self-Check for saturation

Measure the concentration of exhaust gas with gas detector• You can test the filter’s deodorizing ability with a gas detector against the chemicals you are using. Prepare a test under actual working conditions. For example, generate fumes at the hood opening similar to what occurs during your work. Adjust the fan speed, then use gas detector to measure the concentration of the chemical in the exhaust air at the rear outlet.• Compare the result with the chemical’s MSDS and the TLV (Threshold Limit Value) set by ACGIH. If the measured value is higher than the criteria, the filter is saturated or its adsorption efficiency for that chemical has decreased. In this case, contact Jeio Tech for guidance and replace the filter with a suitable one.• Jeio Tech provides gas detector and detecting tubes for six common chemicals:

| Gas Detector | KITAGAWA AP-20 |

|---|---|

| Gas Detecting Tube | Benzene, GASTEC-121SP (0.5~10 ppm) |

| Toluene, GASTEC-122L (1-100 ppm) | |

| Acetic acid, GASTEC-81L (0.125-25 ppm) | |

| Chloroform, GASTEC-137 (4-400 ppm) | |

| Formaldehyde, GASTEC-91L (0.05-1 ppm) | |

| Ammonia, GASTEC-3L (0.5-60 ppm) |

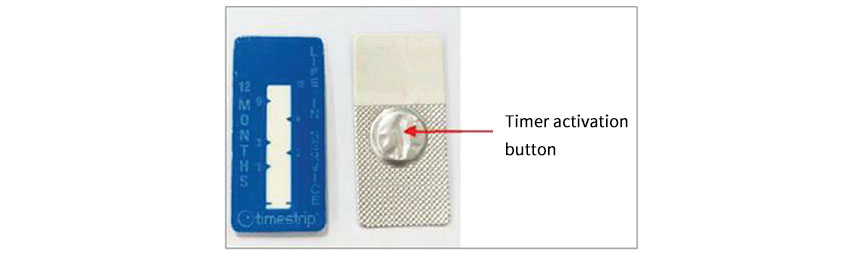

• Note: Jeio Tech uses large-capacity carbon filters. Since saturation time depends on the type of chemical, usage amount, and frequency, it is difficult to predict precisely. We recommend running regular chemical saturation tests. If that is not possible, you can also replace filters on a fixed schedule using a Filter Timer set to a one-year cycle.

Filter timer for one yearBy choosing the right filters and managing replacement with proper testing, you can significantly improve lab safety and efficiency. Cleaner air means better experiments and healthier researches.Start building a safer lab environment with Jeio Tech. 🫡

📩 Need help? Contact us

📚 Check Out Other Parts of This Series

At Jeio Tech, we’re passionate about delivering lab equipment designed to simplify your work and achieve better results by listening to and reflecting on the feedback of users through sales, services, validation, etc.