Oven

OF4-10P Programmable Forced Convection Oven (112L)

Availability:

Available on backorder

Unattended operation is absolutely available with the intelligent programmable controller.

-

120V, 60Hz, US Plug

$4,086.00

Available on backorder

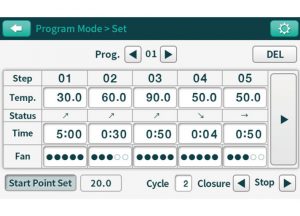

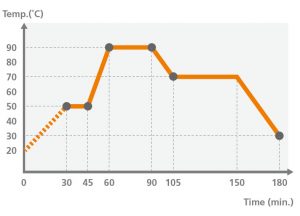

Easy setting program temperature for everyone

- User interface that provides a quick view of temperature changes

(heating, stable, and cooling) and fan speed also. - Set various test condition using 10 programs and 10 steps, which can be repeated up to 99 times.

- Start temperature, temperature and time for each step, and Opti-flowTM all adjustable as desired.

Structural and functional features for improved user convenience

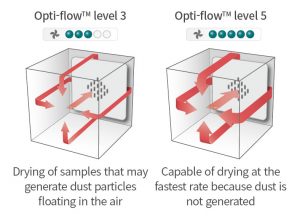

- Opti-flow™, a function to flexibly adjust the fan speed

according to the specimen type and test conditions. - Stacking Kit (optional) ensuring the safe fitting of one unit

to another, thus doubling the amount of work done in a given area for improved space efficiency. - Hands-free™ door system to allow users to easily open

the door while carrying samples with both hands.

Real-time monitoring to check status of device

- BMS communication port that helps monitor the device temperature on the building management system, enabling quick response in case of abnormality. (option)

- Monitor and control via mobile app anytime, anywhere with LC Connected. (mobile monitoring system) (option)

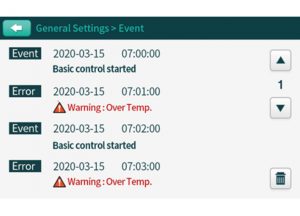

Convenient checking for the test progress and data

- RS-232/USB port and compatible software provided to enable easy device control and data management using PC.

- Test data is automatically saved and easily downloaded via USB;

easy to edit and use. (in CSV format) - 36 latest events, such as errors and door opened or closed, automatically recorded, helping user obtain feedback on experimental results.

Reliable temperature control performance based on stable control mechanisms

- Wide temperature range of up to 250℃.

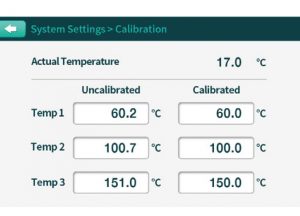

- Three-point temperature calibration that ensures high temperature accuracy over a wide temperature range.

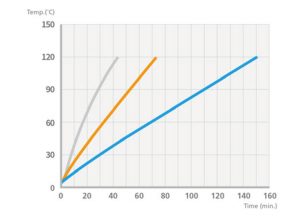

- Ramping rates (℃/min) flexibly adjustable for each test performed.

- Excellent temperature distribution through the formation of optimal airflow for uniform heat transfer.

(±1.9℃ or below at 100℃)

| Model | Solid door (without window) | OF4-10P | ||||||

|---|---|---|---|---|---|---|---|---|

| Window door | OF4-10PW | |||||||

| Chamber volume (L/cu ft) | 112/3.96 | |||||||

| Temperature 1) | Range (℃/℉) | Amb. + 10~250 / Amb. + 18 ~ 482 | ||||||

| Fluctuation at 100℃ (±℃/±℉) | 0.3/0.54 | |||||||

| Variation at 100℃ (±℃/±℉) | 1.7/3.06 | |||||||

| Heating time to 100℃ (min) | 14 | |||||||

| Recovery time at 100℃ (min) | 4 | |||||||

| Control Panel | 5inch TFT Color LCD | |||||||

| Communication interface | USB, RS-232, BMS | |||||||

| Function | Program setting | 10 program, 10 step, start temp. | ||||||

| Scehdular | Set day, time, and program No | |||||||

| Recently event record | 36ea | |||||||

| Fan speed adjustable | Three-step wind speed settings | |||||||

| Recommended temperature | Three frequently used temperature settings suggested | |||||||

| Graph | Available checking the stored and real-time data as graphs | |||||||

| Data storage | Save the test data in CSV format | |||||||

| Temp. ramping rate (℃/min. / ℉/min.) | 0~6/0~10.8 | |||||||

| Dimensions | Interior (W x D x H, mm/inch) | 485 x 350 x 655 / 19.09 x 13.78 x 25.79 |

||||||

| Exterior (W x D x H, mm/inch) | 663 x 677 x 859 / 26.1 X 26.65 X 33.82 |

|||||||

| Net weight (kg/lbs) | 63/138.9 | |||||||

| Shelves | Quantity of shelves (Standard/max.) | 2/8 | ||||||

| Max. Load per shelf (kg/lbs) | 30/66.1 | |||||||

| Number of Air change per hour at 100 ℃ 2) | 18 | |||||||

| Electrical requirements (120V, 60Hz, A) | 12.3 | |||||||

| Cat. No. | Solid door (without window) | AAH12936U | ||||||

| Window door | AAH12976U | |||||||

1) This data was measured when the fan speed was set to Step 5. If the fan speed is set to Step 1 or Step 3, the fluctuation and variation values will increase. (According to DIN 12880, before 2013)

2) This data was measured when the fan speed was set to Step 5. If the fan speed is set to Step 1 or Step 3, the number of air changes may decrease. (According to ASTM D 5374, reapproved 1999)

2) This data was measured when the fan speed was set to Step 5. If the fan speed is set to Step 1 or Step 3, the number of air changes may decrease. (According to ASTM D 5374, reapproved 1999)